Construction of a Six-Bay Aircraft Maintenance Hangar for SR Technics

Project Details

Project overview

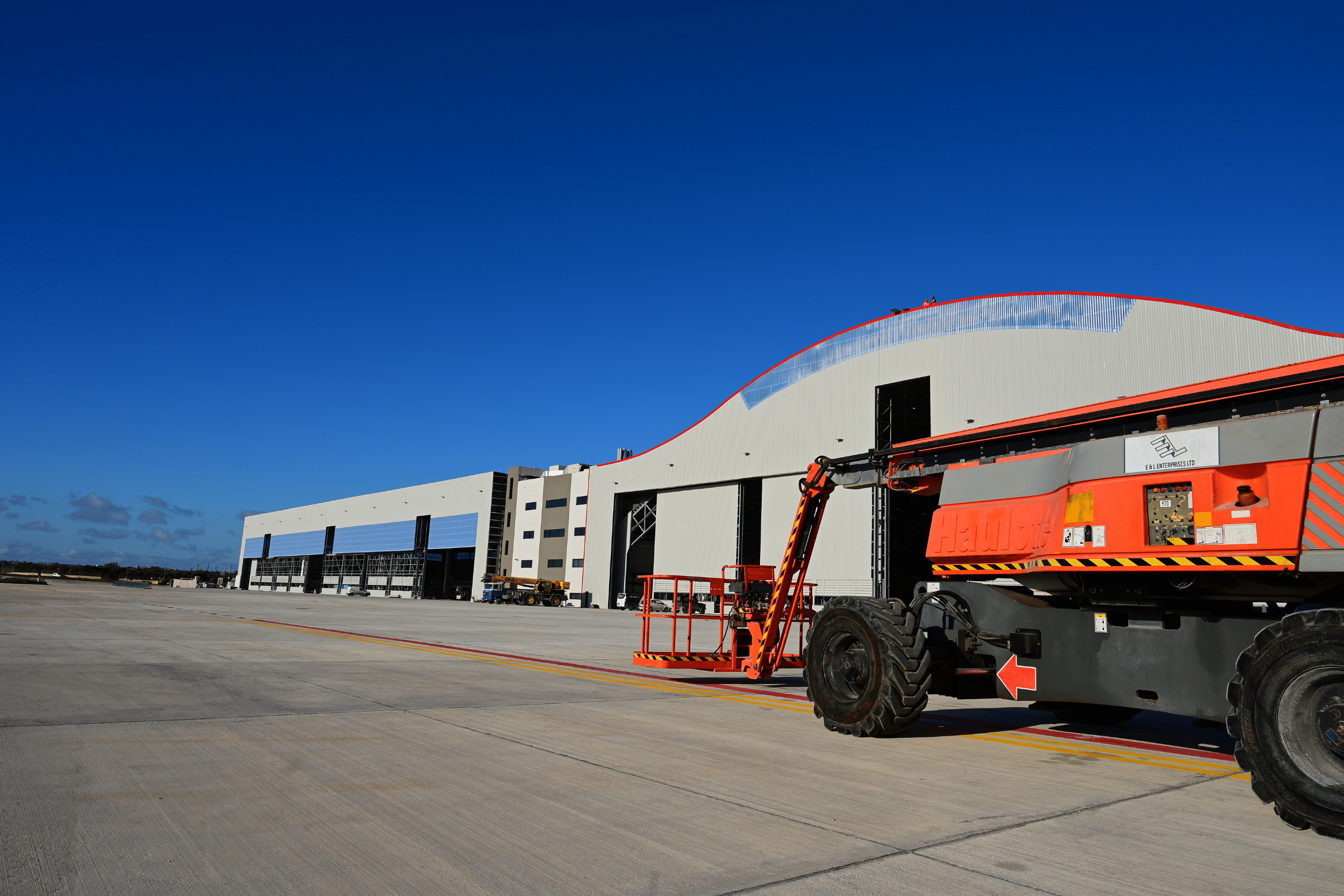

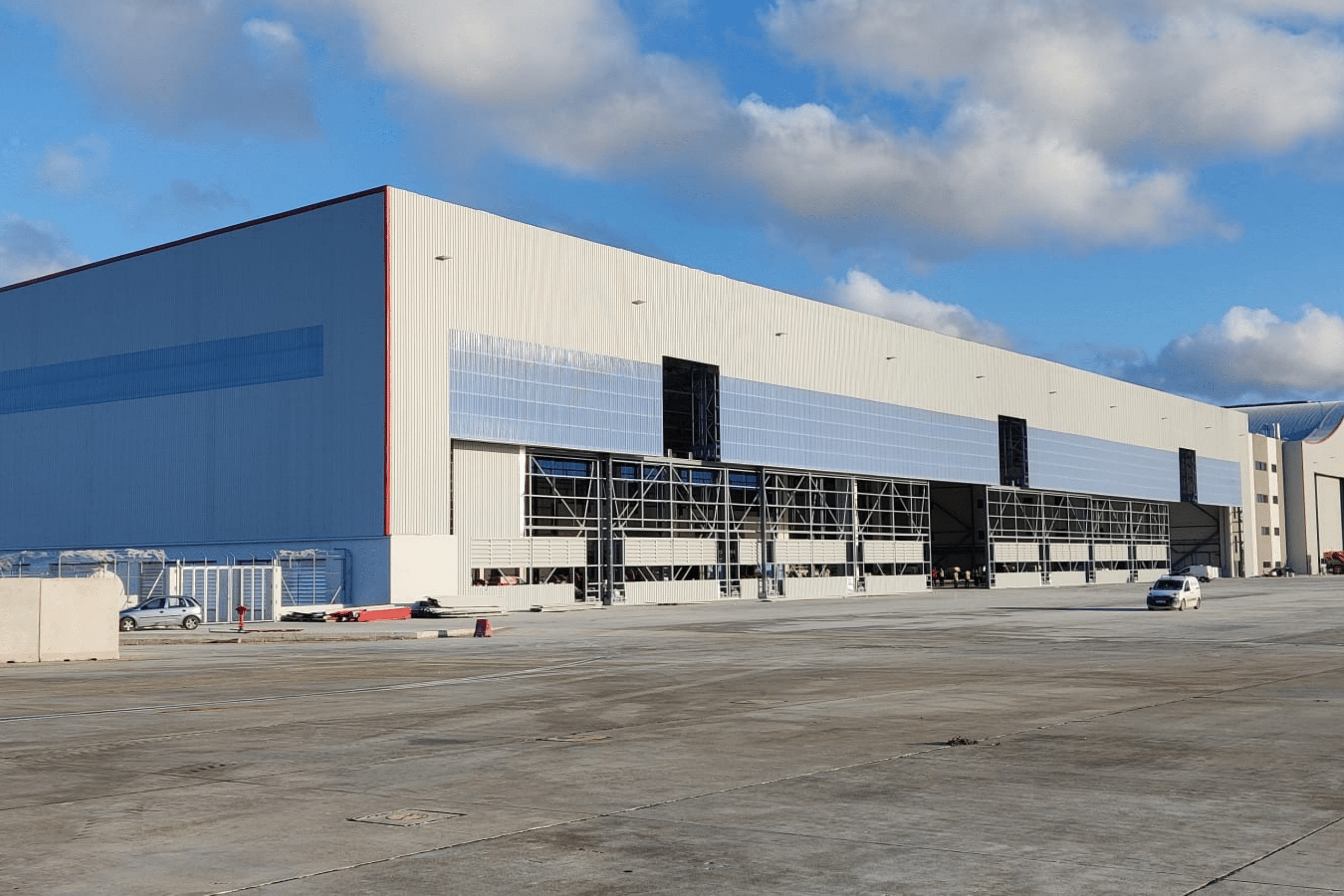

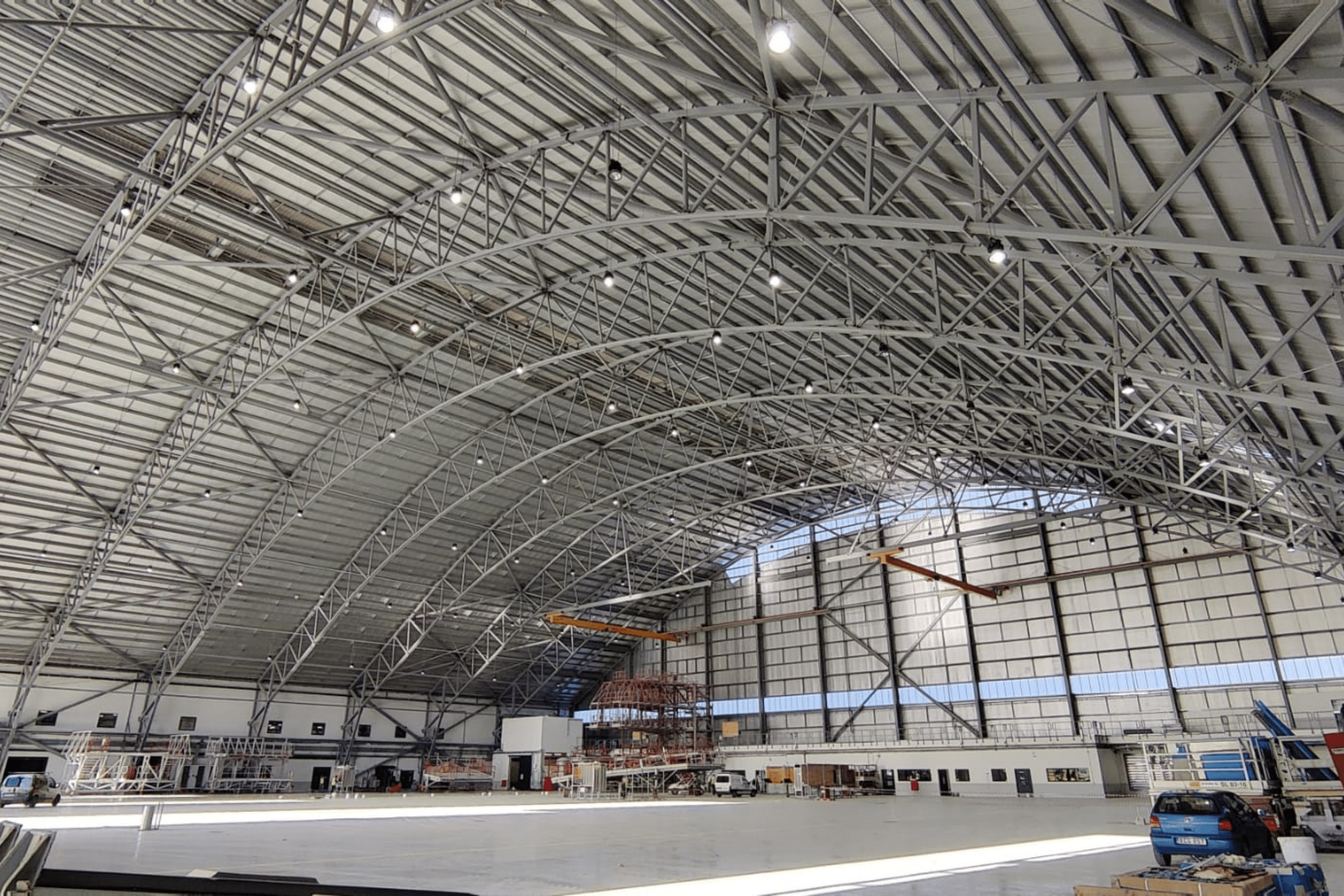

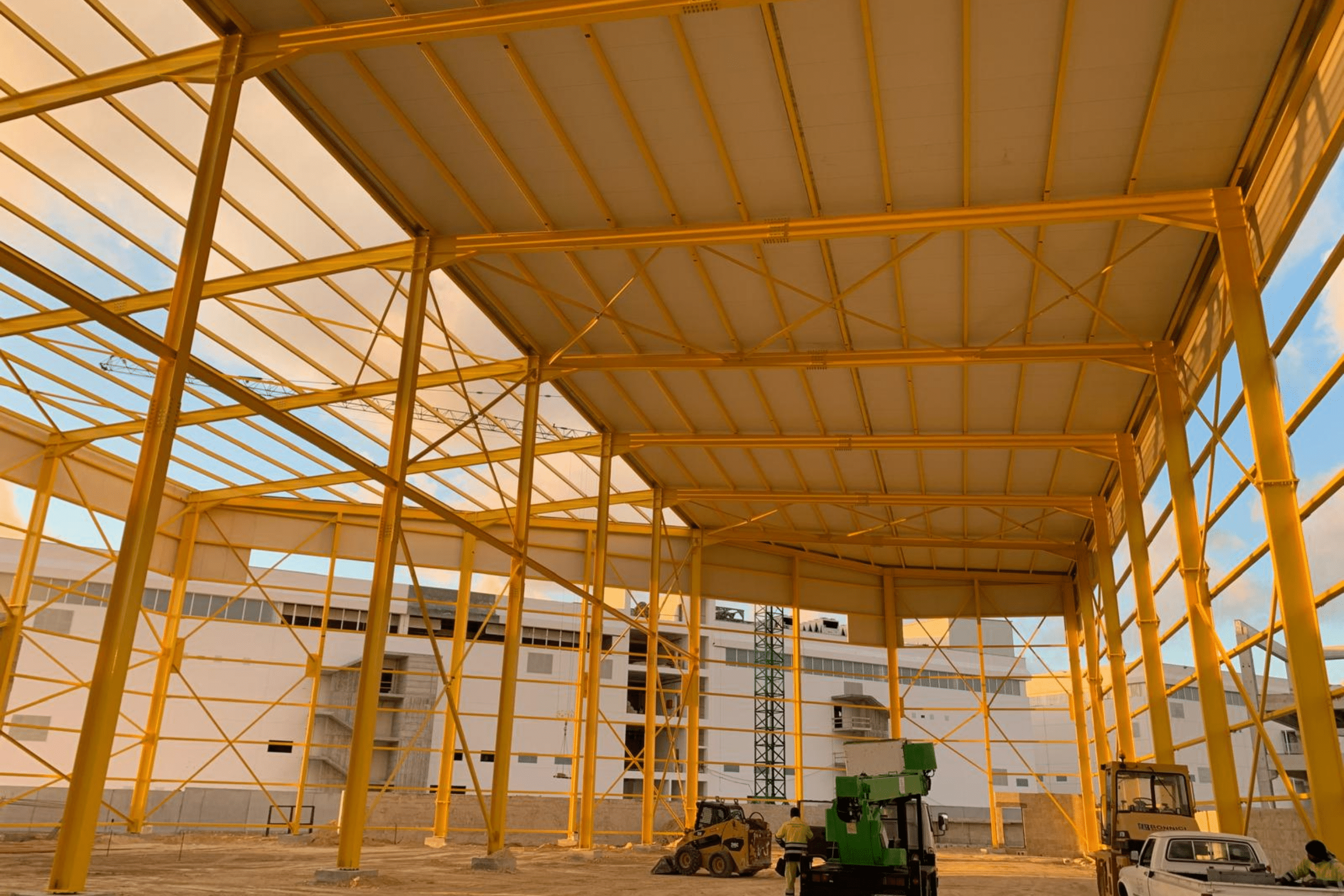

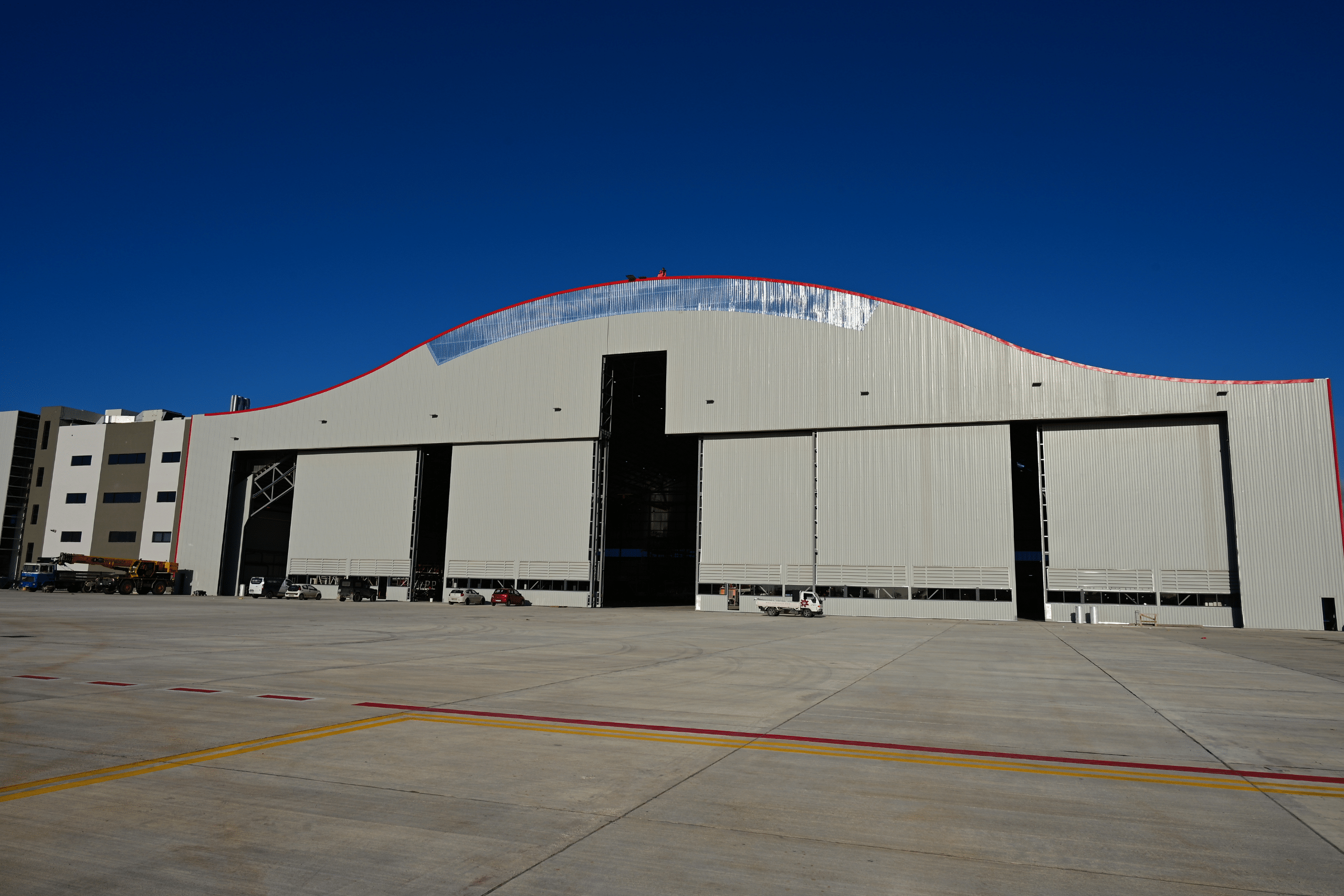

E&L Enterprises was entrusted with the structural steel fabrication and assembly for a six-bay aircraft maintenance hangar developed for SR Technics at Malta International Airport. The 40,000 m² facility was designed to accommodate six narrow-body aircraft simultaneously, supporting heavy maintenance operations, C-checks, and cabin modifications.

Now owned and operated by easyJet, the hangar meets the stringent technical, safety, and operational standards required by a globally recognised airline. With a total project value of €42 million, E&L was responsible for approximately €5.9 million worth of structural steel works, delivered under tight timelines and demanding quality requirements.

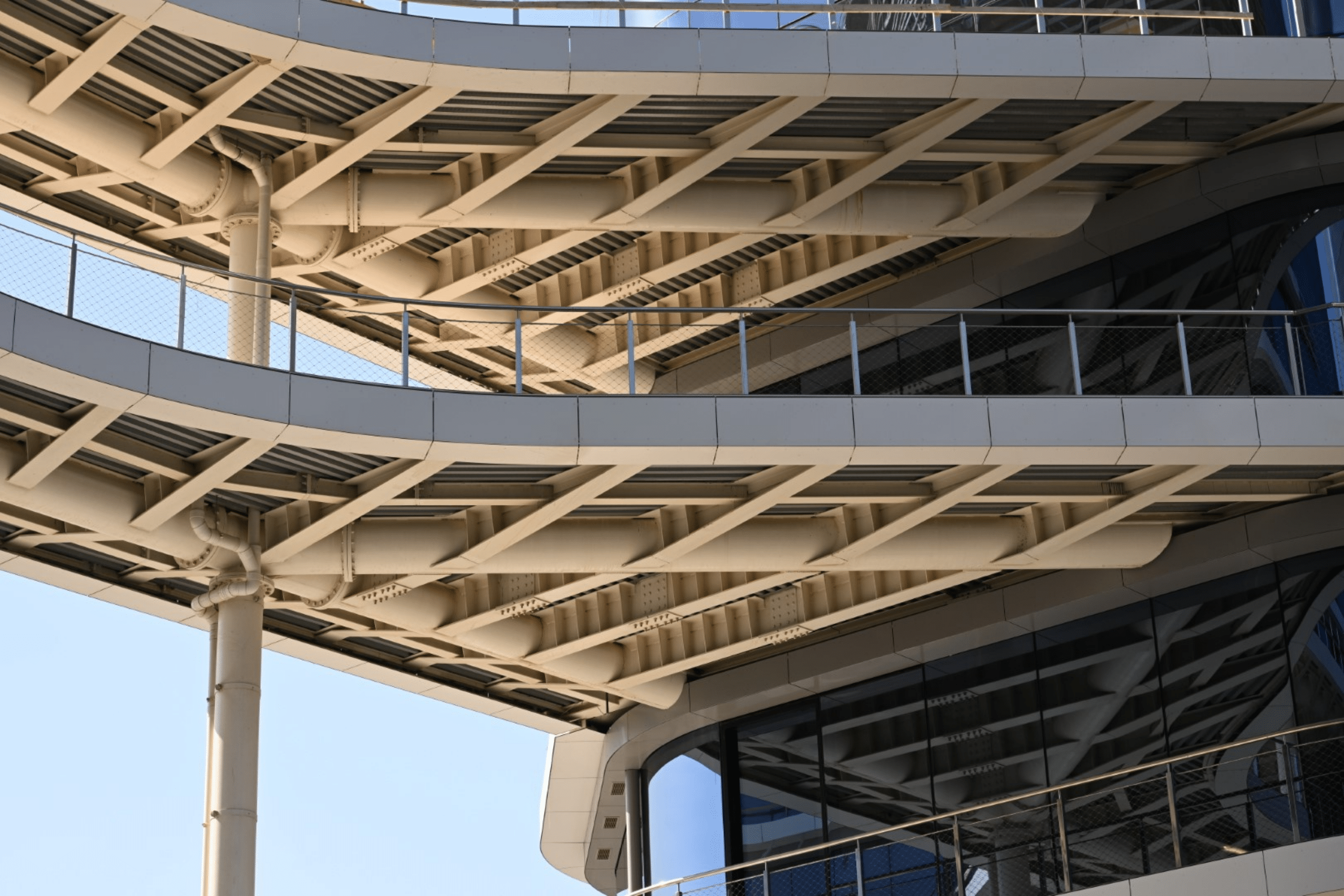

Structural design and engineering

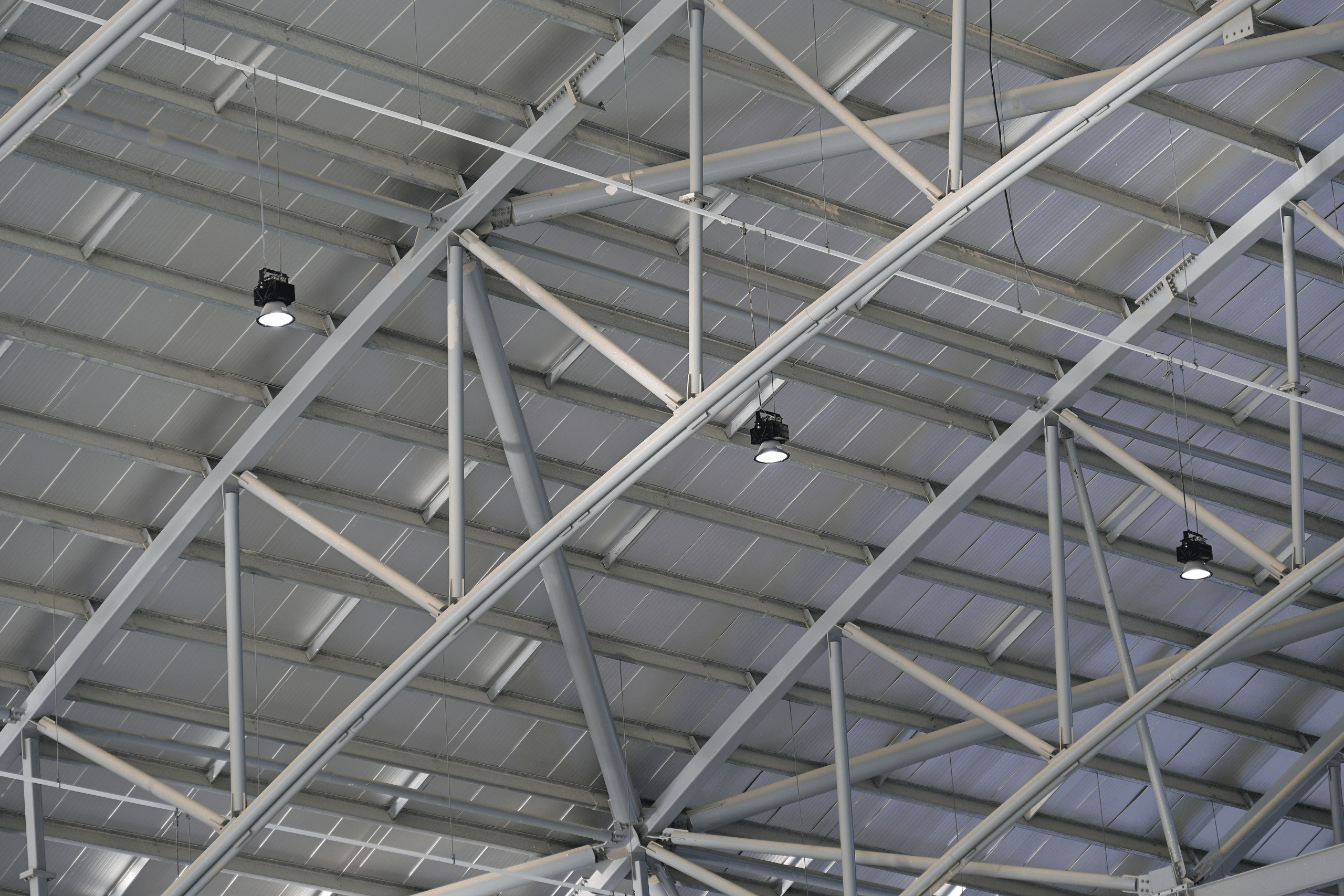

Working closely with architects and engineers, E&L developed detailed fabrication and assembly drawings based on the approved architectural and technical specifications. Structural calculations and compliance reviews were carried out to ensure full adherence to aviation safety standards and engineering regulations.

NC files were prepared for CNC machining, enabling high-precision cutting, drilling, and milling of all structural elements. This level of preparation ensured accuracy across the entire fabrication process and reduced on-site adjustments during installation.

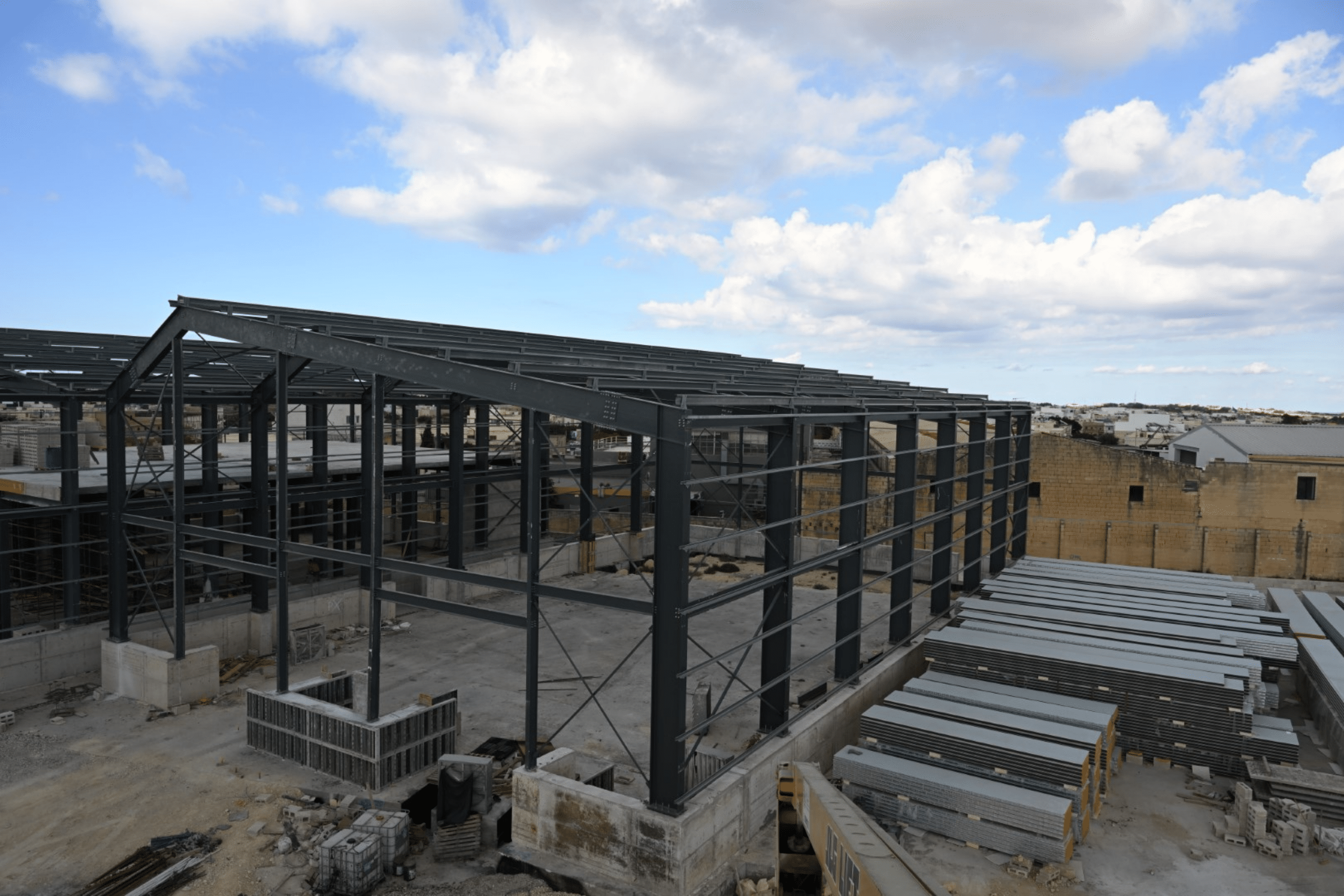

Fabrication and production

The scale and complexity of the hangar required a highly efficient production process. E&L utilised advanced CNC laser, plasma, and waterjet cutting technologies to manufacture steel components to millimetre precision. Automated beam processing systems were used to cut, drill, and notch large structural sections with consistency and accuracy.

At peak production, the facility processed between 30 and 40 tonnes of structural steel per week, allowing the project to remain ahead of schedule throughout the fabrication phase.

Surface treatment and protective coating

To meet aviation safety and durability requirements, all steelwork underwent specialised surface treatment and coating processes. A 120-minute intumescent fire protection system was applied in line with aviation regulations, providing critical fire resistance.

C5M-grade corrosion-resistant epoxy coatings were used to protect the structure in the exposed airport environment. Paint adhesion and quality control tests were carried out to verify compliance with client and regulatory specifications.

Installation and on-site coordination

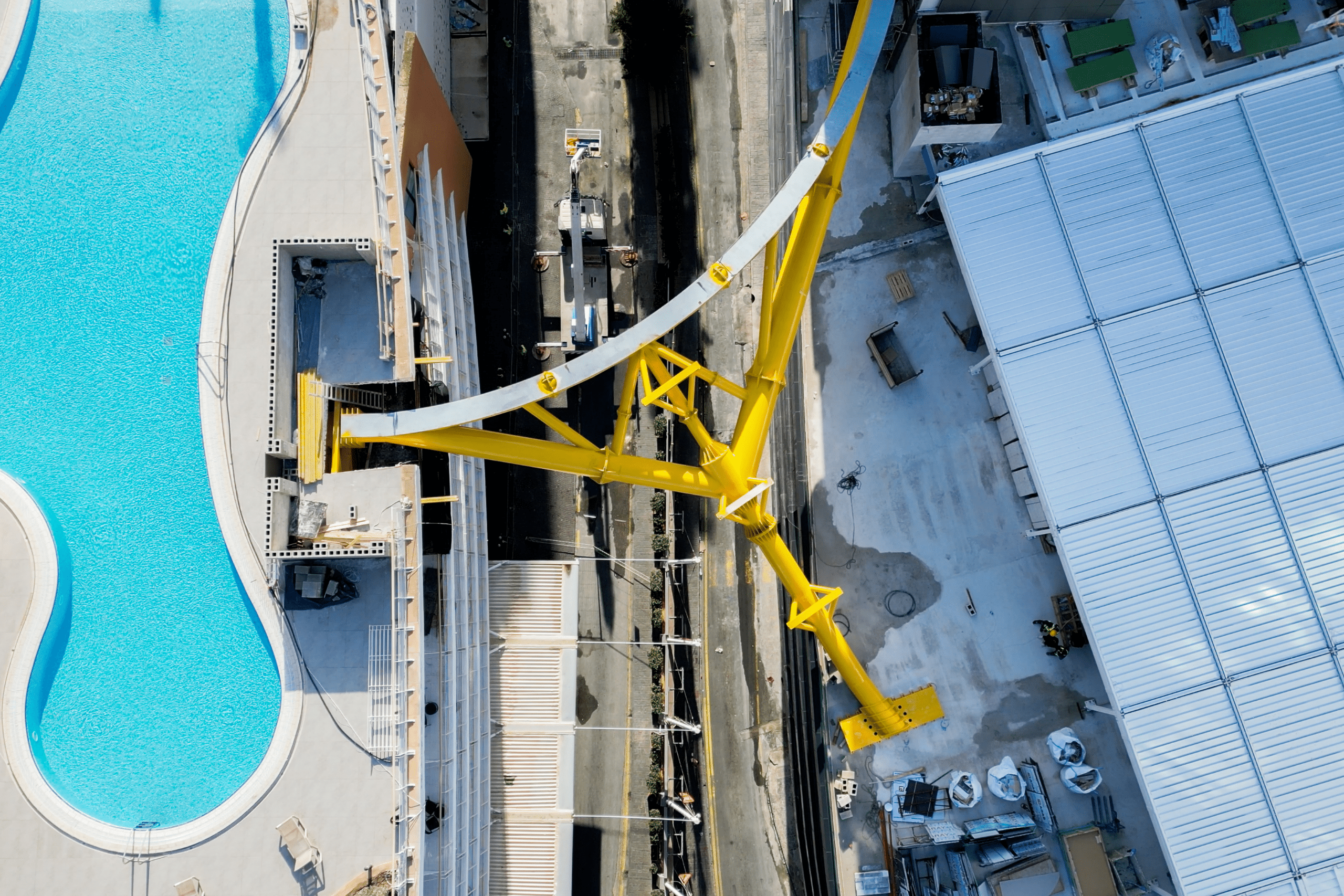

Bulk steel production was completed within a four to five month period, meeting all structural milestones. Large components were pre-assembled off-site to streamline installation and minimise on-site work.

E&L coordinated the use of mobile cranes for lifting long-span trusses and major structural elements. Bolted connections were installed with precise torque control under the supervision of structural engineers, ensuring full compliance with design requirements.

Key challenges and solutions

The project was delivered within a ten month timeframe, requiring meticulous scheduling, automation, and coordination across all stages of production and installation.

The hangar’s curved steel truss geometry demanded exceptional precision. CNC cutting and controlled pre-assembly ensured accurate alignment and efficient installation on site.

Logistics planning played a critical role. Sequenced deliveries and pre-fabrication strategies reduced on-site handling and improved overall efficiency.

Throughout the project, E&L adhered strictly to ISO 9001, ISO 1090-2, and ISO 3834 standards. Daily inspections, non-destructive testing including magnetic particle and ultrasonic testing, and full material traceability ensured the highest levels of quality and compliance.

Result

The completed hangar provides SR Technics and easyJet with a state-of-the-art maintenance facility that supports safe, efficient, and large-scale aircraft operations. The project stands as a strong example of E&L Enterprises’ capability to deliver complex, high-value structural steel solutions within the aviation sector.

10

6

25

40,000

Want to Start A Project?

Let’s turn your plans into reality. Whether you need structural design, fabrication, or full project delivery, our team is ready to support you from concept to completion. Share your project details below, and we’ll get in touch to discuss how we can help.

Contact

"*" indicates required fields