Service Details

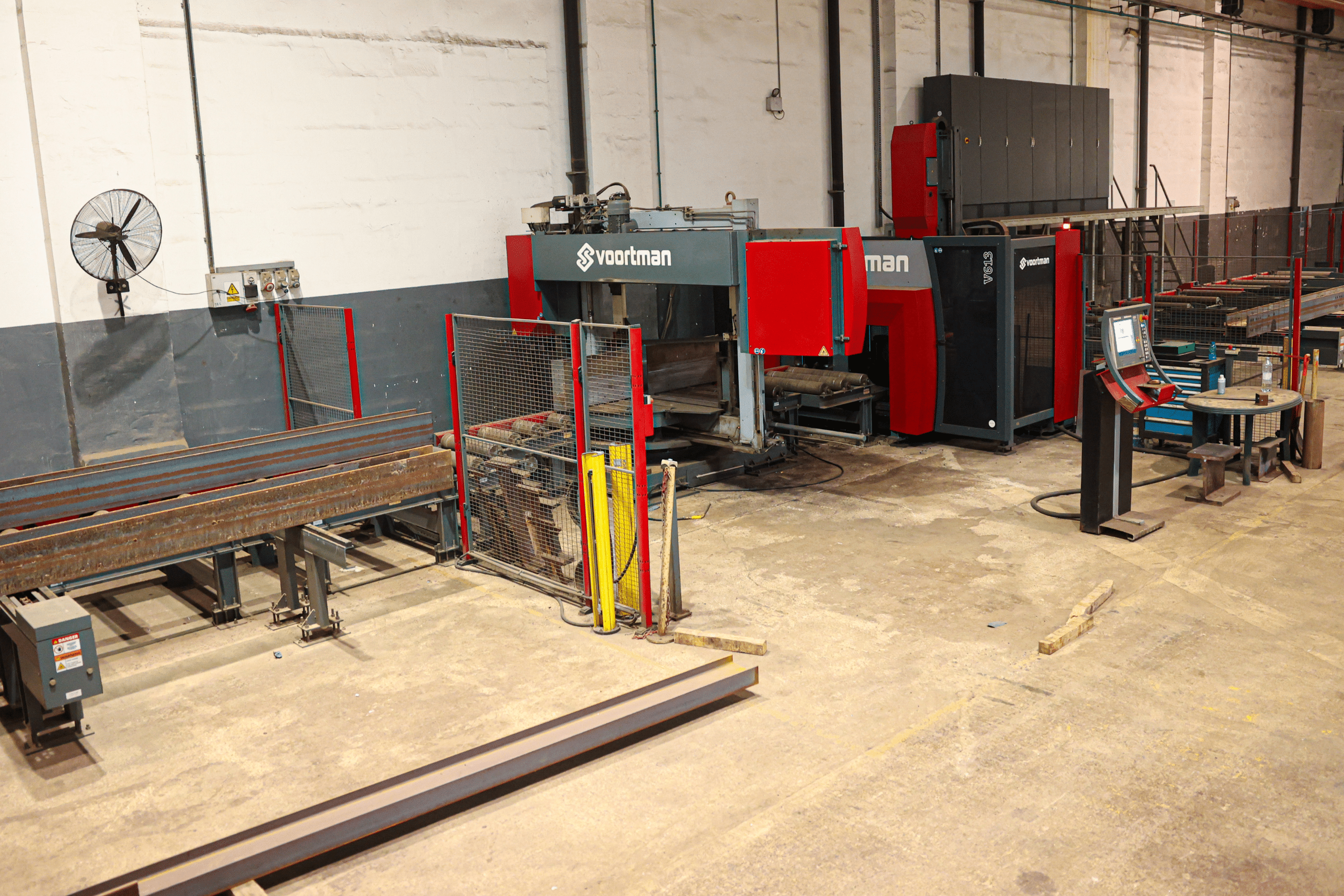

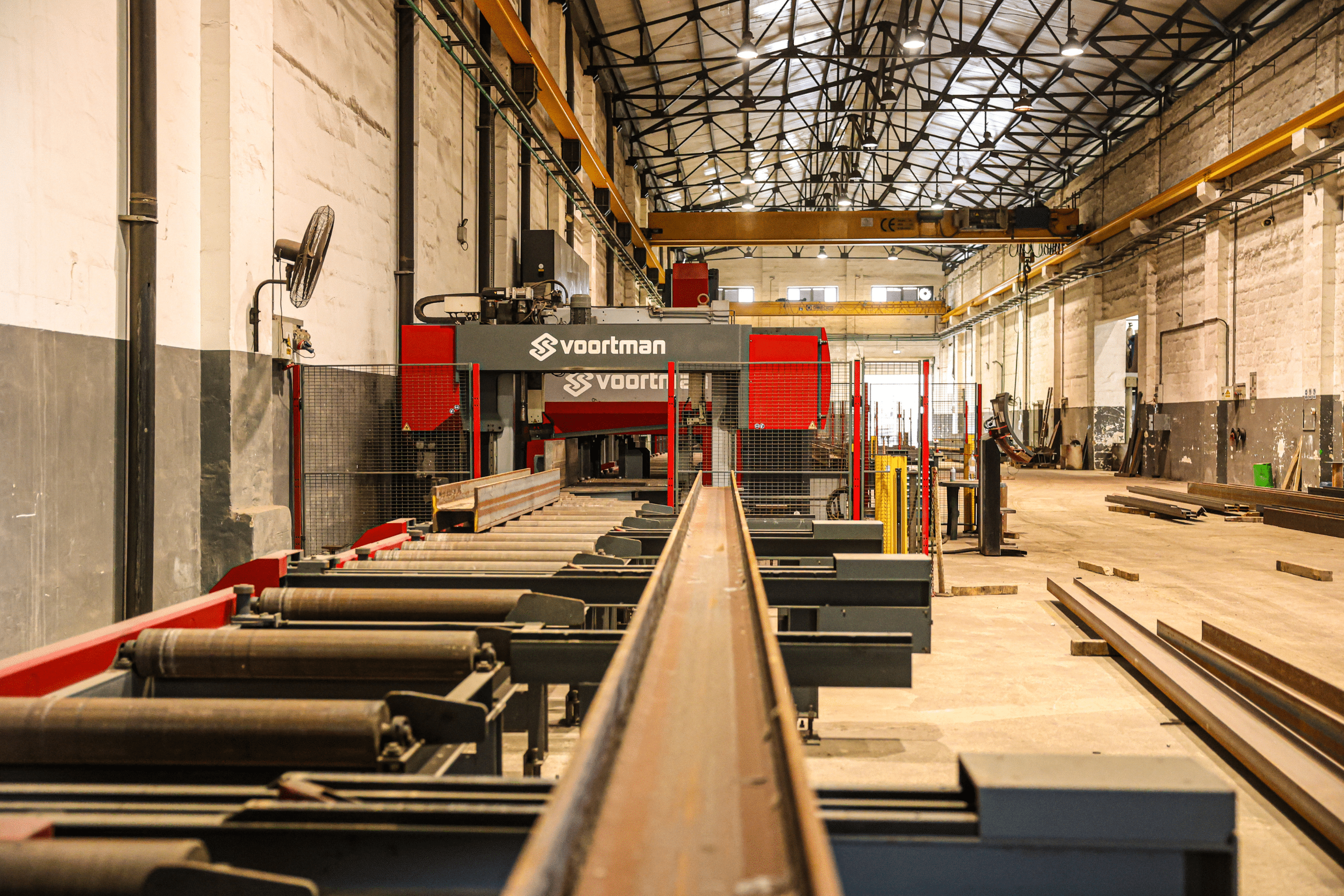

CNC beam processing is a core part of our fabrication capability, allowing us to deliver precision, consistency, and efficiency across every project. Using advanced automated systems, we cut, drill, notch, and chamfer steel beams with accuracy that meets the most demanding specifications.

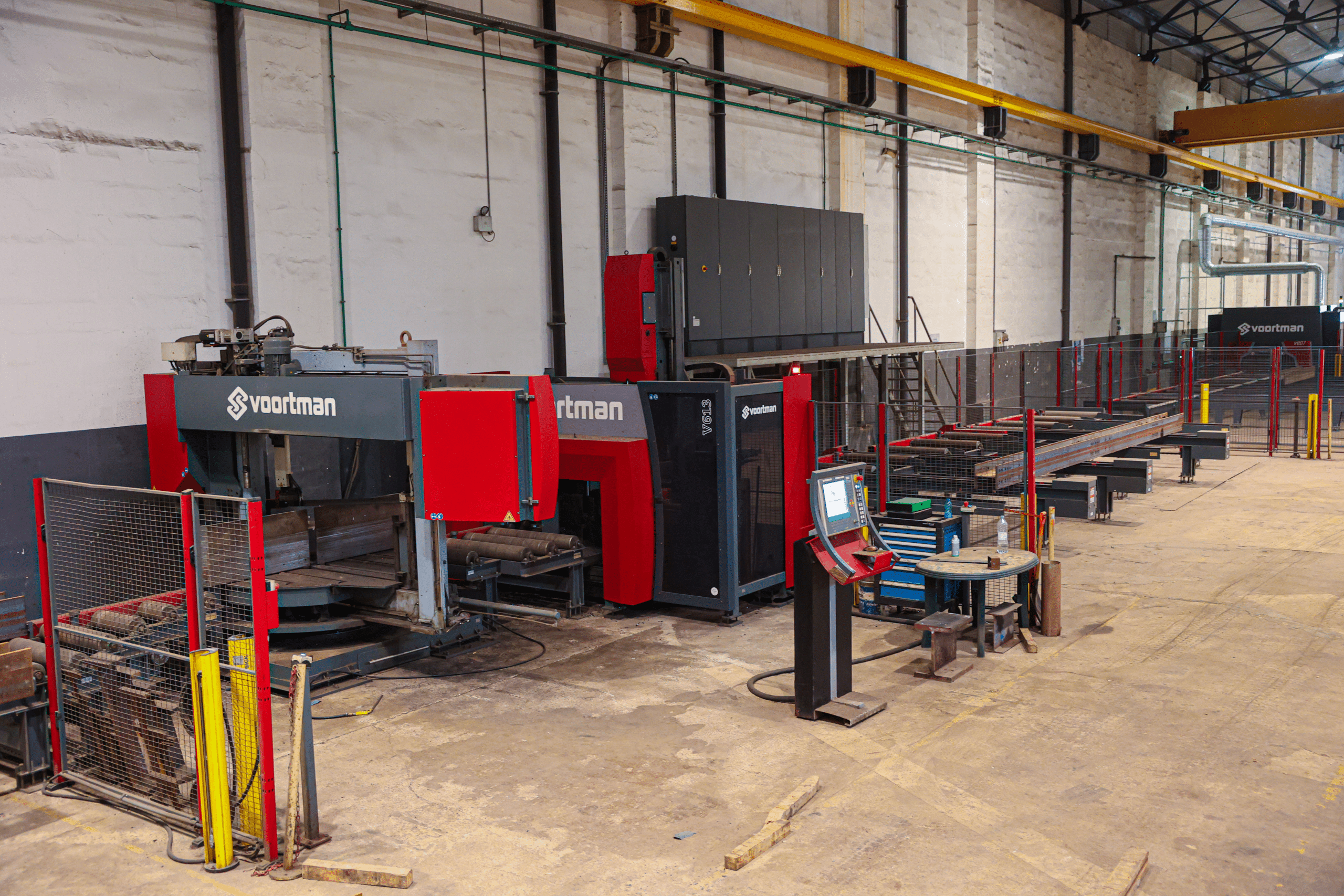

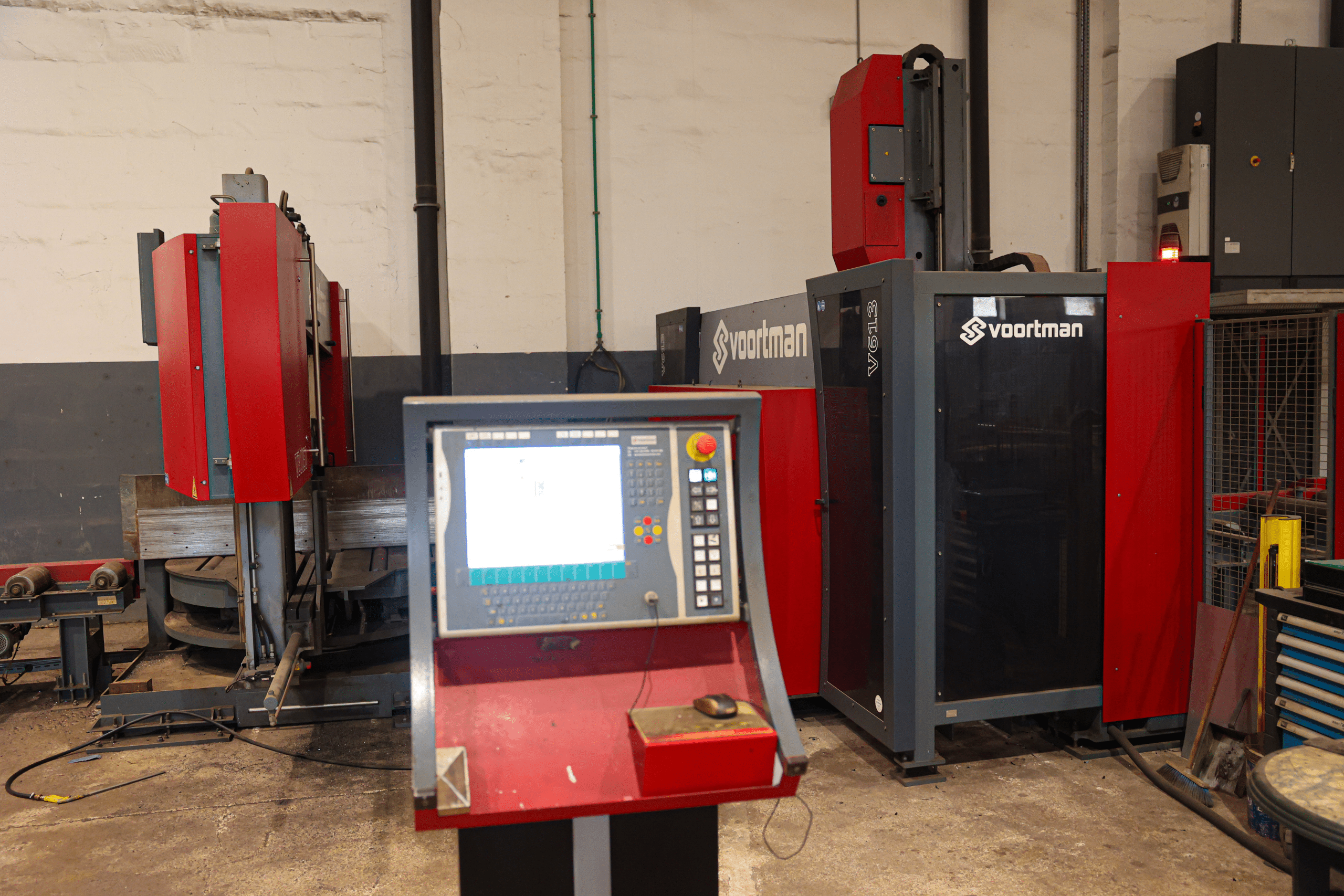

Our facility is equipped with CNC beam cutting and drilling machines, along with robotic plasma technology designed to manage complex profiles and high-volume workloads. This combination enables us to achieve clean finishes, reduce waste, and provide reliable results throughout the production process.

Capabilities

Our CNC beam processing equipment supports a wide range of structural applications, including:

-

High-precision cutting for universal beams, columns, channels, angles, and hollow sections

-

Automated drilling for bolt holes and connection details

-

Notching and slotting for structural assemblies

-

Chamfering for clean, safe, ready-to-install components

-

Plasma cutting for complex shapes and non-standard geometries

-

Consistent repeatability for high-volume fabrication runs

These capabilities ensure that every beam is processed accurately and efficiently, reducing on-site adjustments and supporting faster project delivery.

Technology and accuracy

Our CNC systems are built to maintain dimensional accuracy throughout the entire process. Automated measurement, cutting, and drilling routines eliminate manual error, ensuring the finished product matches the original design intent. This level of precision improves compatibility with adjoining elements and contributes to smoother installation on site.

Industries we support

We provide CNC beam processing services for a range of sectors, including:

-

Industrial and manufacturing

-

Commercial developments

-

Infrastructure and civil works

-

Aviation and logistics

-

Energy and utilities

-

Architectural and bespoke steelwork

By combining advanced machinery with skilled operators, we support both large-scale projects and specialised, one-off requirements.

Why choose E&L for CNC beam processing

Choosing E&L means working with a team that prioritises accuracy, reliability, and timely delivery. Our CNC beam processing capabilities integrate seamlessly with our wider fabrication services, providing a streamlined path from design and detailing through to manufacturing and installation. This end-to-end approach ensures every component fits first time, reducing project risk and improving overall performance.

Want to Start A Project?

Let’s turn your plans into reality. Whether you need structural design, fabrication, or full project delivery, our team is ready to support you from concept to completion. Share your project details below, and we’ll get in touch to discuss how we can help.

"*" indicates required fields